The art of maintaining and restoring the sleek appearance of your wheels can be achieved through the use of a wheel repair lathe. This remarkable piece of machinery offers a solution for revitalizing worn or damaged wheels and bringing them back to their former glory. Whether you’re a car enthusiast or a professional in the automotive industry, understanding the power and capabilities of a wheel repair lathe can greatly enhance your ability to provide top-notch wheel repair services.

One type of wheel repair lathe that has gained significant popularity is the vertical wheel repair lathe. This innovative machine comes equipped with cutting-edge technology that allows for precision repairs on a wide range of wheel types. From alloy wheels to steel rims, the vertical wheel repair lathe can effectively address issues such as curb rash, scratches, and even more severe wheel damage.

When it comes to choosing the right wheel repair lathe, it’s important to consider the quality and reliability of the manufacturer. That’s where Alloy Wheel Repair Machine, available at wheelcncmachine.com, comes into play. As the official website of Taian Haishu Machinery Co., Ltd., a professional designer, manufacturer, and supplier of CNC wheel machinery, they offer an extensive range of wheel repair lathe options to suit your specific needs.

With the Ultimate Guide to Wheel Repair with a Lathe, you’ll discover step-by-step instructions on how to maximize the potential of your wheel repair lathe. From understanding the different functions and features to mastering the art of precision cutting, this guide will provide you with all the necessary knowledge to revive your wheels and achieve professional-level results.

So, get ready to embark on a journey of wheel restoration and discover the incredible capabilities of a wheel repair lathe. Let’s revitalize your wheels and bring back that showroom shine!

Types of Wheel Repair Lathes

When it comes to wheel repair lathes, there are several types that offer different capabilities and features. Understanding these types can help you choose the right machine for your specific needs. Let’s explore the three main types of wheel repair lathes.

-

Benchtop Wheel Repair Lathe:

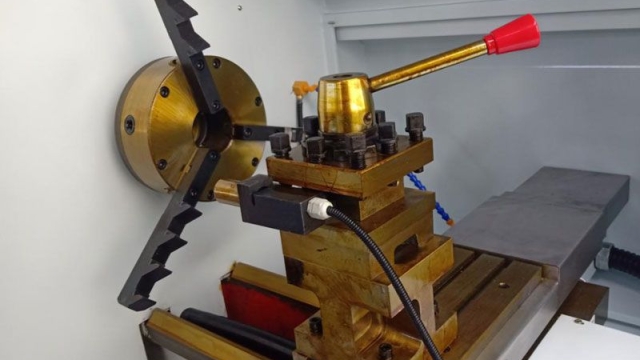

The benchtop wheel repair lathe is a compact and portable option that allows for efficient wheel repairs. It is designed to be placed on a workbench or similar surface, making it suitable for small-scale operations or limited workspace. Despite its smaller size, this type of lathe still delivers precise and high-quality results, making it an ideal choice for hobbyists or small repair shops. -

Vertical Wheel Repair Lathe:

The vertical wheel repair lathe offers greater flexibility and versatility compared to its benchtop counterpart. This type of lathe is designed with a vertical orientation, allowing for easy mounting and dismounting of wheels. The vertical configuration also enables the lathe to handle a wide range of wheel sizes and weights, making it suitable for professional repair shops or automotive service centers. With its advanced features, the vertical wheel repair lathe ensures efficient and accurate repairs, enhancing the overall quality and durability of the wheels. -

CNC Wheel Repair Machine:

The CNC wheel repair machine takes wheel repair to the next level with its automated and computer-controlled capabilities. This type of lathe is equipped with advanced software and precision tools, allowing for precise and complex wheel repairs. It can perform a variety of tasks, such as cutting, shaping, and polishing, with minimal human intervention. The CNC wheel repair machine is commonly used in large-scale wheel repair facilities, where efficiency and precision are paramount. With its state-of-the-art technology, this machine ensures consistent and high-quality repairs that meet the standards of the automotive industry.

By understanding the different types of wheel repair lathes available, you can make an informed decision when choosing a machine that suits your specific requirements. Whether you opt for a compact benchtop lathe, a versatile vertical lathe, or an automated CNC machine, a properly selected wheel repair lathe can revive your wheels and extend their lifespan effectively.

Benefits of Using a Wheel Repair Lathe

A wheel repair lathe offers numerous advantages for restoring the condition of your wheels. Whether you need to fix minor damage or completely transform the appearance of your alloy wheels, this machine can work wonders. Let’s explore three key benefits of using a wheel repair lathe.

Firstly, a wheel repair lathe provides exceptional precision and accuracy. With its advanced CNC technology, the lathe can precisely remove imperfections, such as scratches, curb rash, and dents, from the surface of the wheel. The automated process ensures consistent results, leaving your wheels looking smooth and flawless. By utilizing this machinery, you can achieve a professional-level finish that enhances the overall aesthetics of your vehicle.

Secondly, using a vertical wheel repair lathe allows for superior versatility. This type of lathe is specifically designed to handle a wide range of wheel sizes and designs, making it suitable for various vehicles, from cars to trucks. The adjustable settings and customizable options enable you to tailor the repair process according to your specific needs. Whether you want to restore original factory specifications or create a unique custom design, a vertical wheel repair lathe can accommodate your requirements with ease.

Lastly, the use of a wheel repair lathe can be a cost-effective solution compared to replacing your wheels entirely. Rather than investing in new wheels, which can be quite expensive, the lathe allows you to restore and revitalize your existing ones. By removing damage and imperfections, the lathe extends the lifespan of your wheels while saving you money. Additionally, the ability to refinish and customize the wheels gives you the opportunity to personalize your vehicle without breaking the bank.

In conclusion, the benefits of using a wheel repair lathe are evident. From its precision and accuracy to its versatility and cost-effectiveness, this machine proves to be an invaluable tool for wheel restoration. With a wheel repair lathe, you can breathe new life into your wheels, enhancing both the appearance and the value of your vehicle.

Choosing the Right Wheel Repair Lathe

When it comes to choosing the right wheel repair lathe, there are a few factors to consider in order to make an informed decision. Firstly, it is important to assess the size and type of wheels you will be working with. Different lathes are designed to handle various wheel sizes and materials, so ensuring compatibility is crucial for achieving optimal repair results.

Secondly, consider the features and capabilities offered by the wheel repair lathe. Look for a lathe that offers precision in its operation, allowing for accurate and smooth cutting. Additionally, a lathe with adjustable speed settings can be advantageous, as it provides versatility for working with different materials and wheel types.

Lastly, take into account the reputation and reliability of the manufacturer. A reputable supplier, such as wheelcncmachine.com, provides assurance of product quality and customer support. Conducting research and reading reviews can help guide you in selecting a reliable and trustworthy supplier.

By carefully considering these factors, you can choose the right wheel repair lathe that meets your specific needs and requirements. Whether you are working with vertical wheel repair lathes or Alloy Wheel Repair Machines, finding the perfect fit ensures efficient and effective wheel repairs.